See all our articles

Arrange with Ease, Install with Confidence!

Whether you are a beginner or experienced in finishing projects, there are simple ways to successfully install your casings. With the right techniques, every cut can transform the look of a room. Discover five easy and effective installation methods to achieve a result perfectly suited to your style.

Before you start

Before you start

- Make sure you have good lighting.

- Take measurements of your wall before starting to adjust your plans and make the necessary calculations for completing the project.

Material required

Material required

Find all the materials you need at a retailer near you.

- Measuring tape

- Erasable pencil or masking tape

- Level

- Miter saw

- Finishing nailer

- 18 gauge finishing nails

- Grain filler

- Caulk

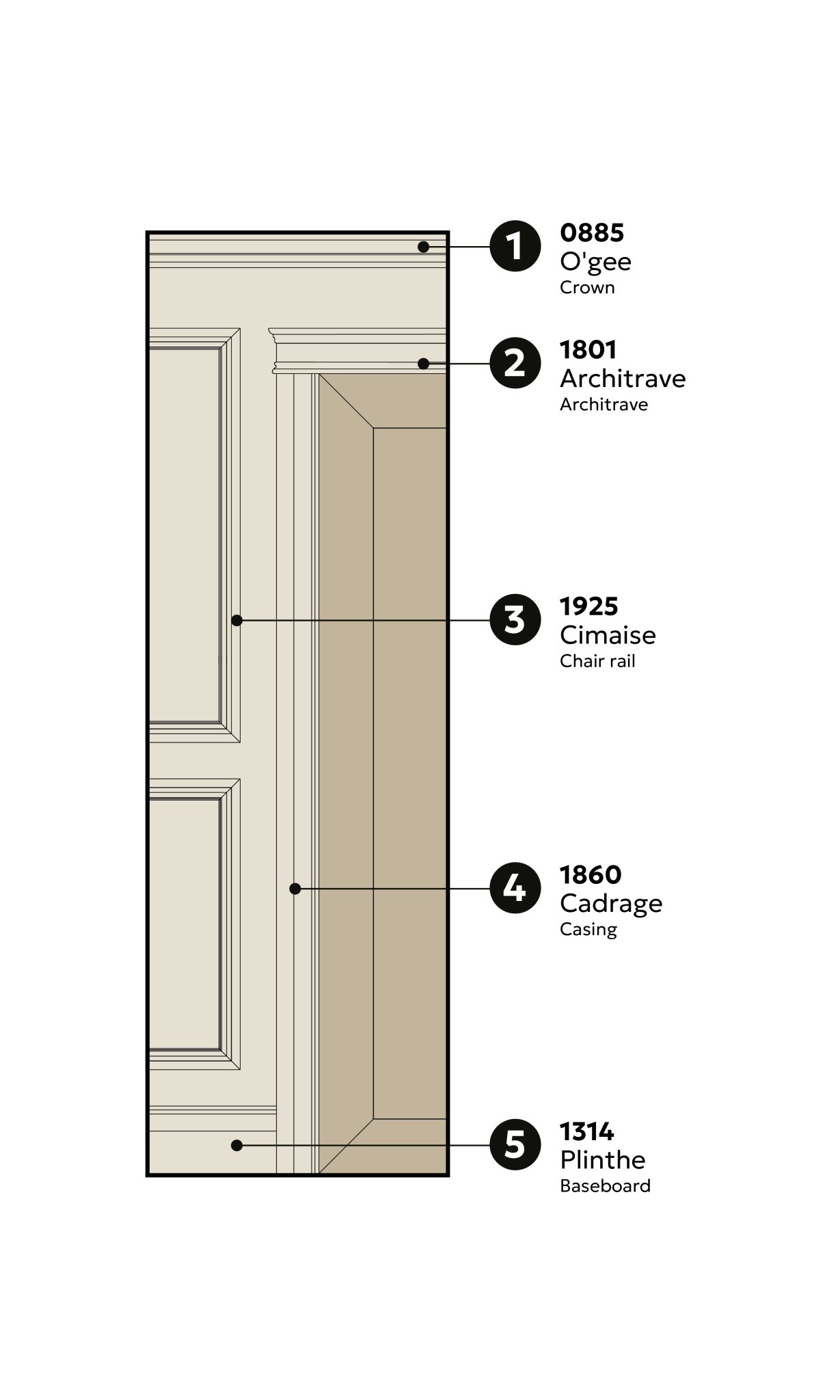

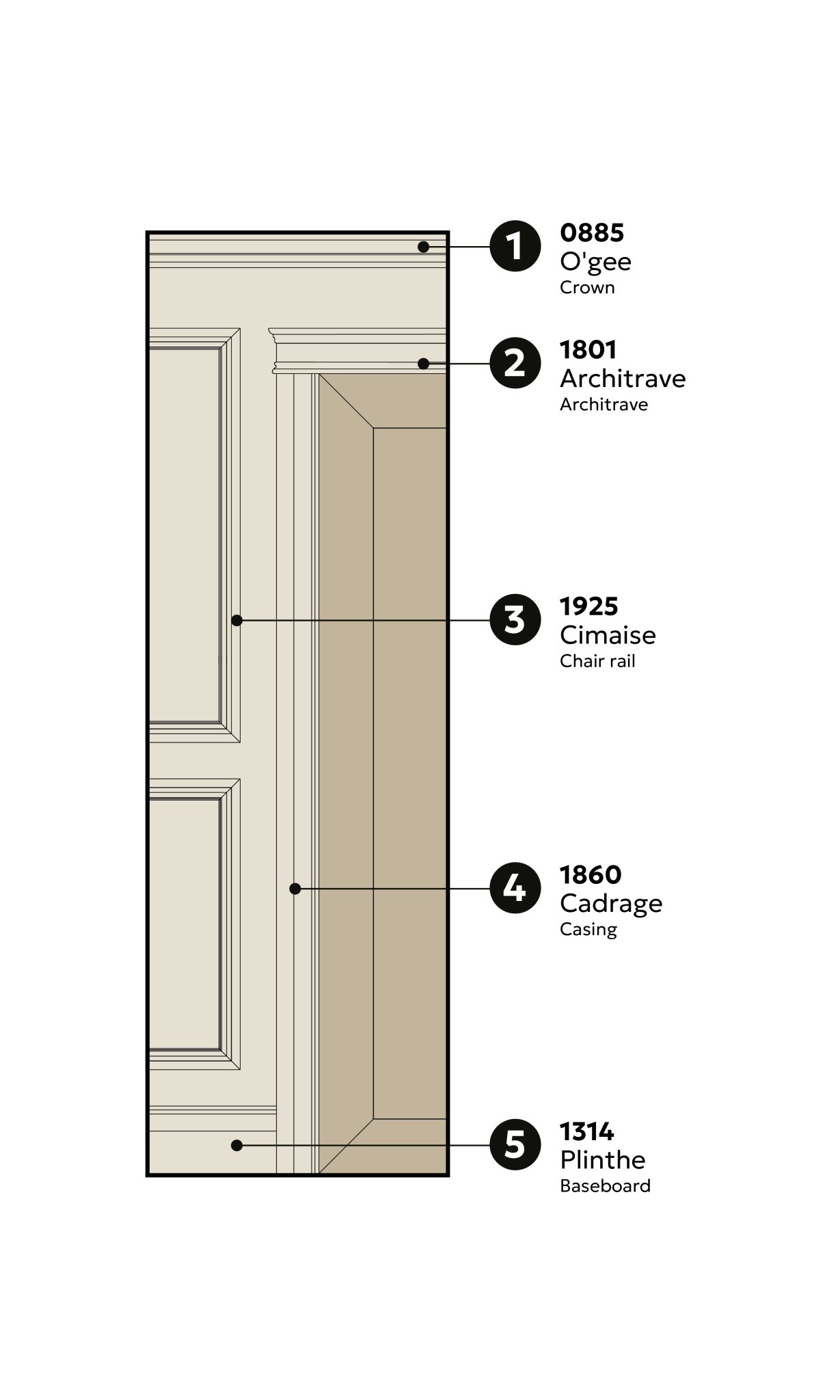

Arrangement 1

In this arrangement :

1. 0885 |Crown

2. 1801| Architrave

3. 1925 | Chair rail

4. 1860| Casing

5. 1314 | Baseboard

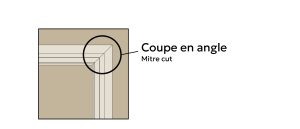

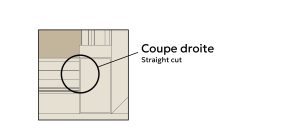

Mitre Cut

A mitre cut consists of trimming the ends of the mouldings at 45° so that two pieces meet to form a 90° corner. By assembling all four corners this way, you get a box, door casing, or window casing with clean and continuous angles. This technique makes the joints nearly invisible and provides a polished, professional finish.

Tips and tricks !

Tips and tricks !

Learn how to make 45° cuts in our web series.

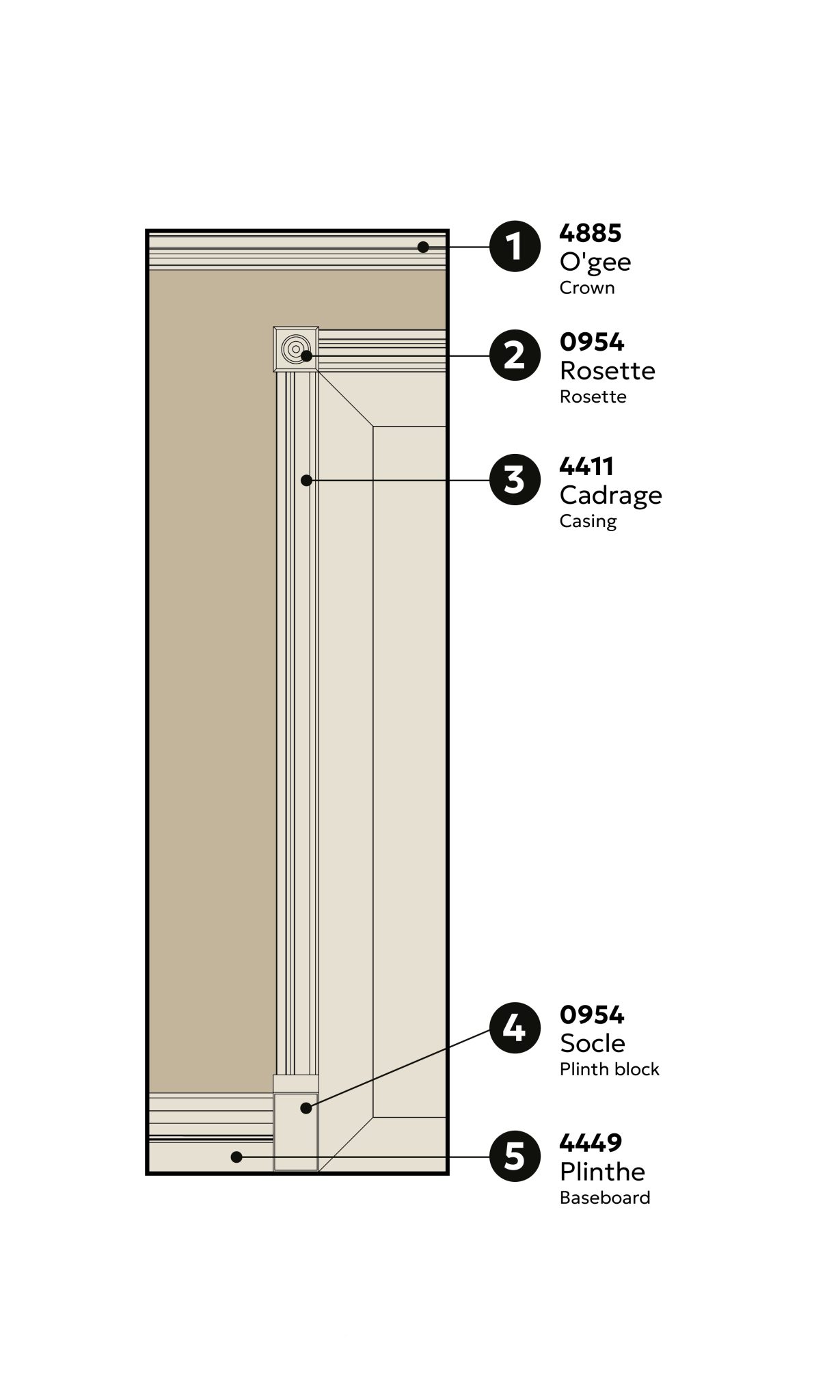

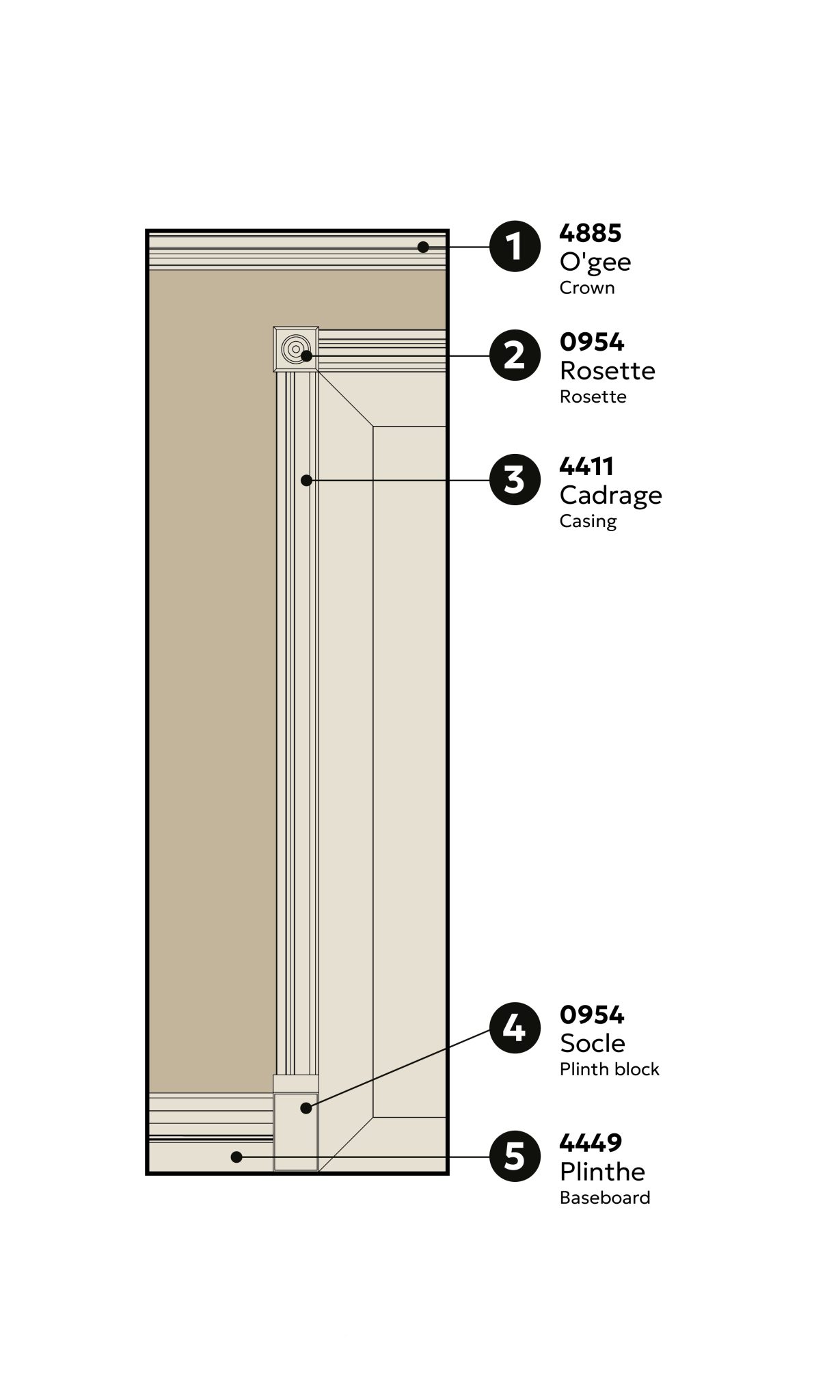

Arrangement 2

In this arrangement :

1. 4885 |Crown

2. 0954| Rosette

3. 4411 | Casing

4. 0954| Plinth block

5. 4449 | Baseboard

Straight Cut

A straight cut consists of cutting the ends of mouldings perpendicular (at 90°) so they meet another piece directly. This technique allows door and window casings, as well as baseboards, to terminate neatly into rosettes or plinth blocks. It provides a clean and simple finish, ideal for a classic and precise look.

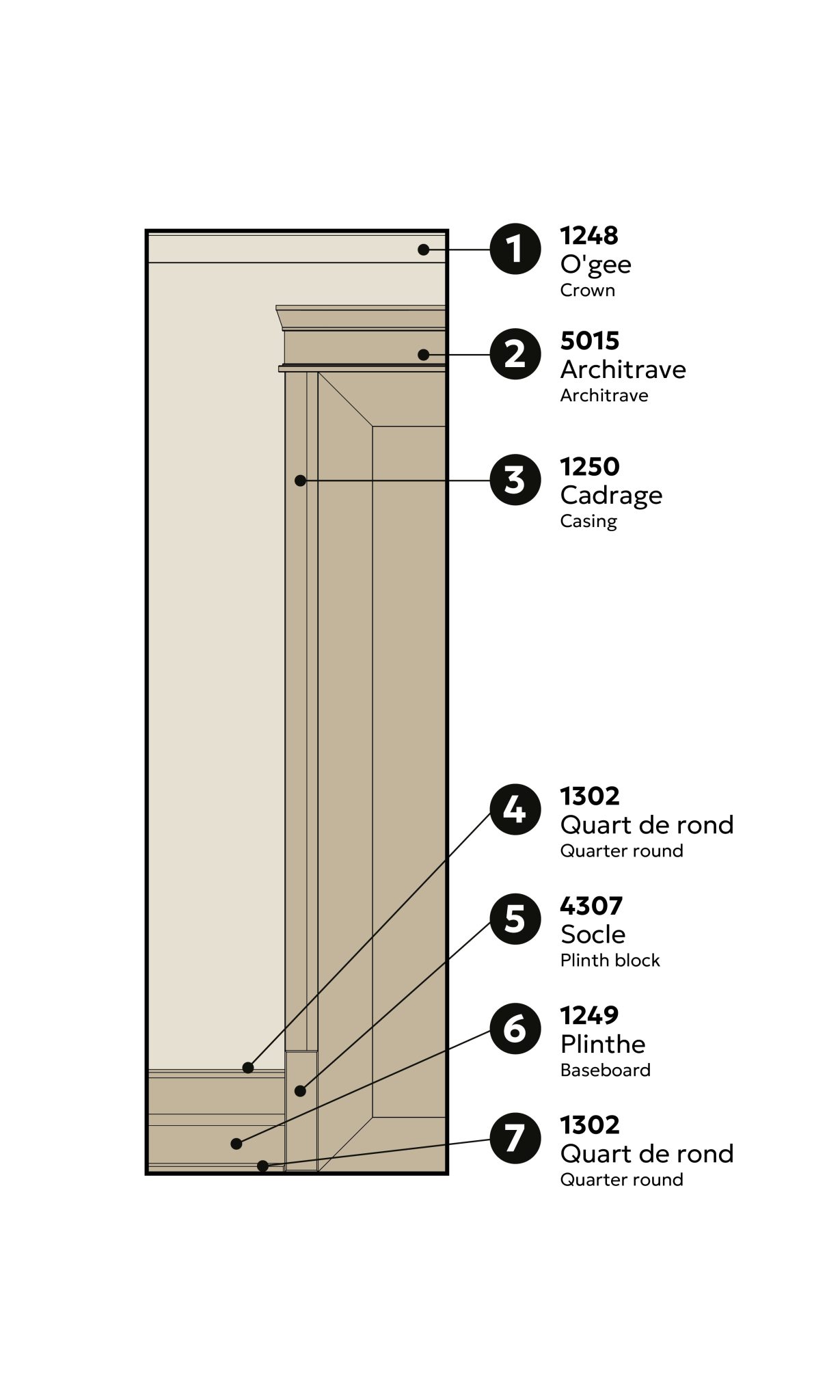

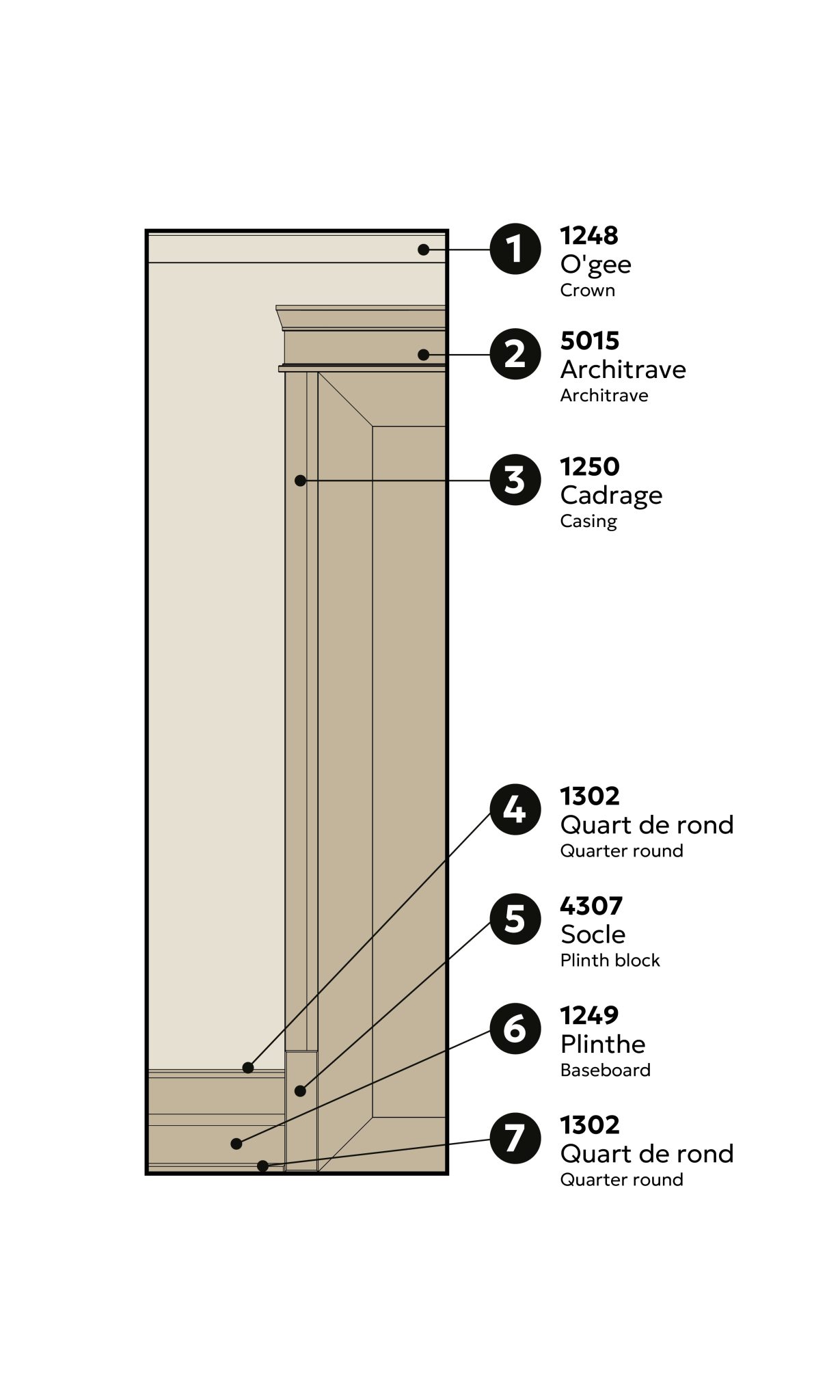

Arrangement 3

In this arrangement :

1. 1248 | Crown moulding

2. 5015| Architrave

3. 1250| Casing

4. 1302| Quarter round

5. 4307 Plinth block

6. 1249 | Plinthe

7. 1302| Quarter round

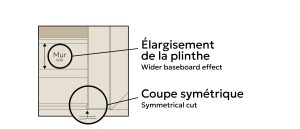

Symmetrical Cut

The symmetrical cut consists of adjusting the chamfer, the small beveled surface of the quarter round, so that it aligns perfectly with the plinth block.

Generally, a plinth block should be thicker than, or at least equal in thickness to, the casing or baseboard.

In this example, the combined quarter round and baseboard (6 & 7) have a thickness of 15/16″, while the plinth block (5) has a thickness of 12/16″. A chamfer is cut on the end of the quarter round at an angle that reflects, like a mirror, the profile of the plinth block while giving the appearance that the moulding is equal to it.

This technique provides a harmonious, polished finish with a professional look.

Wider baseboard effect

This technique consists of installing a quarter round a few inches above the existing baseboard, then painting the wall between the two the same colour as the baseboard and quarter round. It creates the appearance of a wider, more substantial baseboard while achieving this effect at a lower cost.

Tips and tricks !

Tips and tricks !

Watch our web series to choose the right plinth block.

Learn more about plinth block installation in our web series.

Watch our web series to enhance your baseboards.

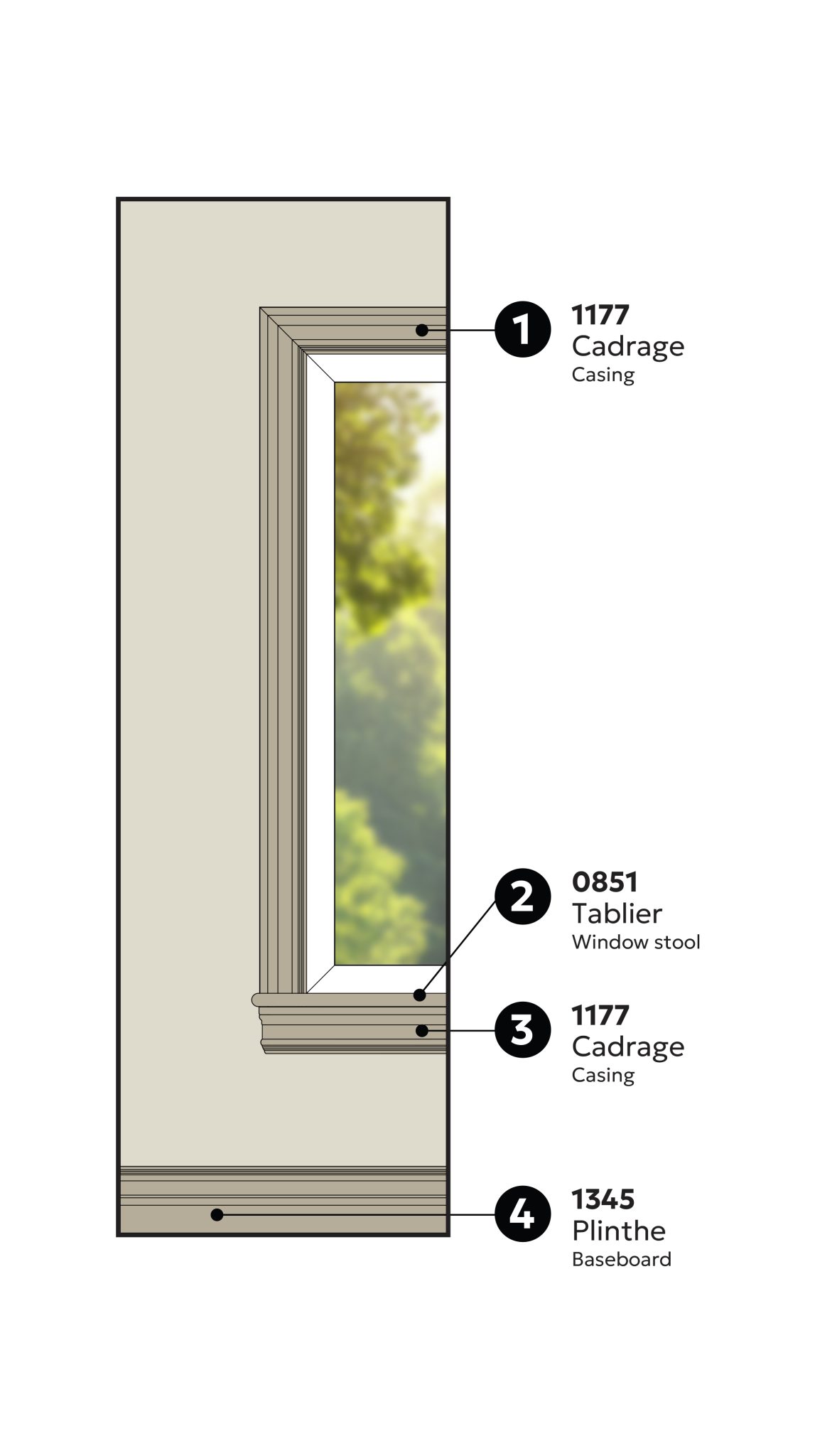

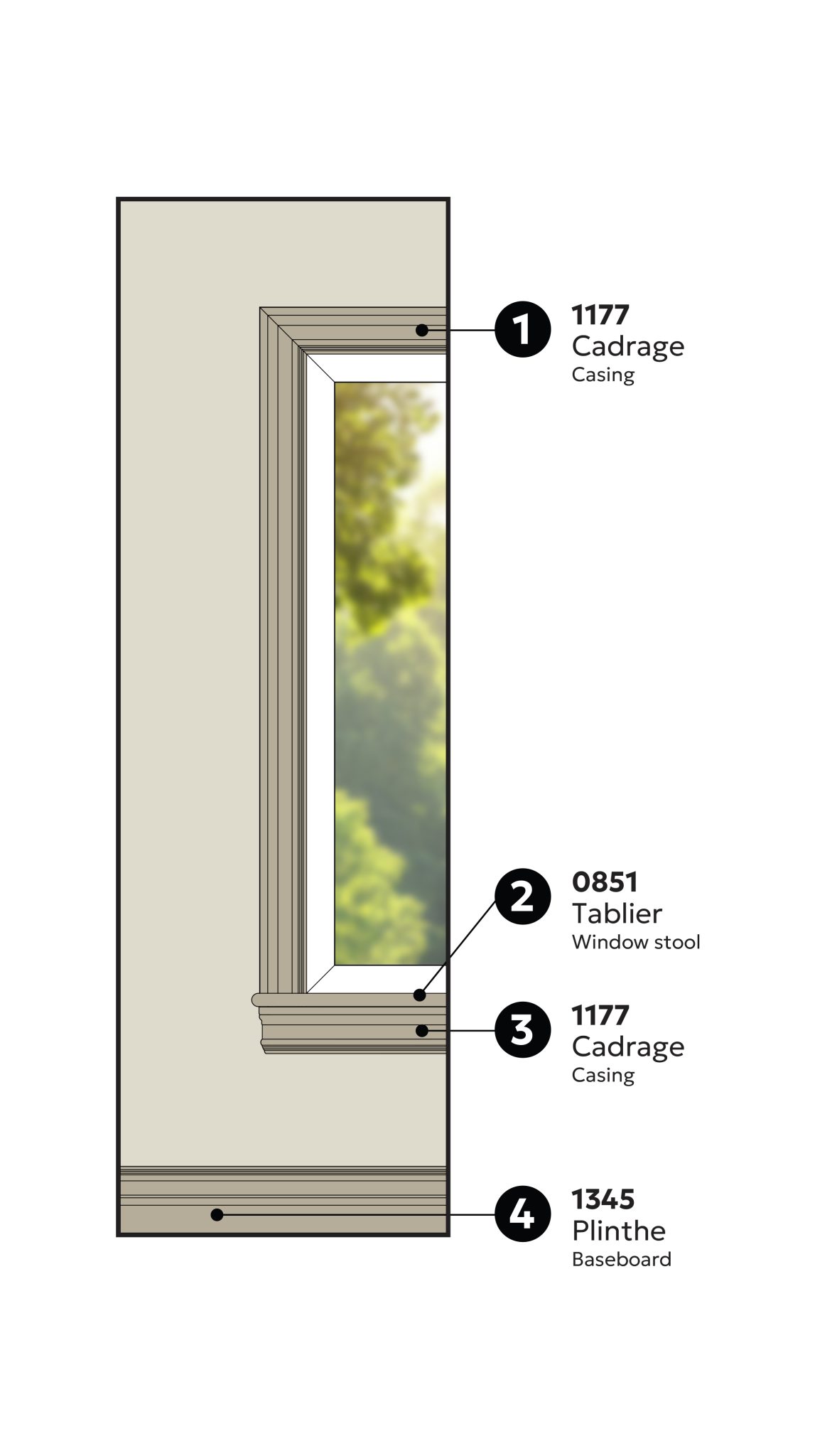

Arrangement 4

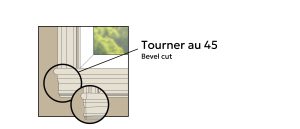

Bevel Cut

Unlike the classic 45° cut, this technique involves turning the window stool and bottom casing only at the ends. The face moulding is cut at 45° on both ends, while the turning mouldings are beveled only on the end joined to the face moulding. This method creates a smooth visual transition between the stool and casing, providing a neat and harmonious finish.

![]() Tips and tricks !

Tips and tricks !

Watch our web series to follow the correct installation order.

Learn how to make a bevel cut in our web series.

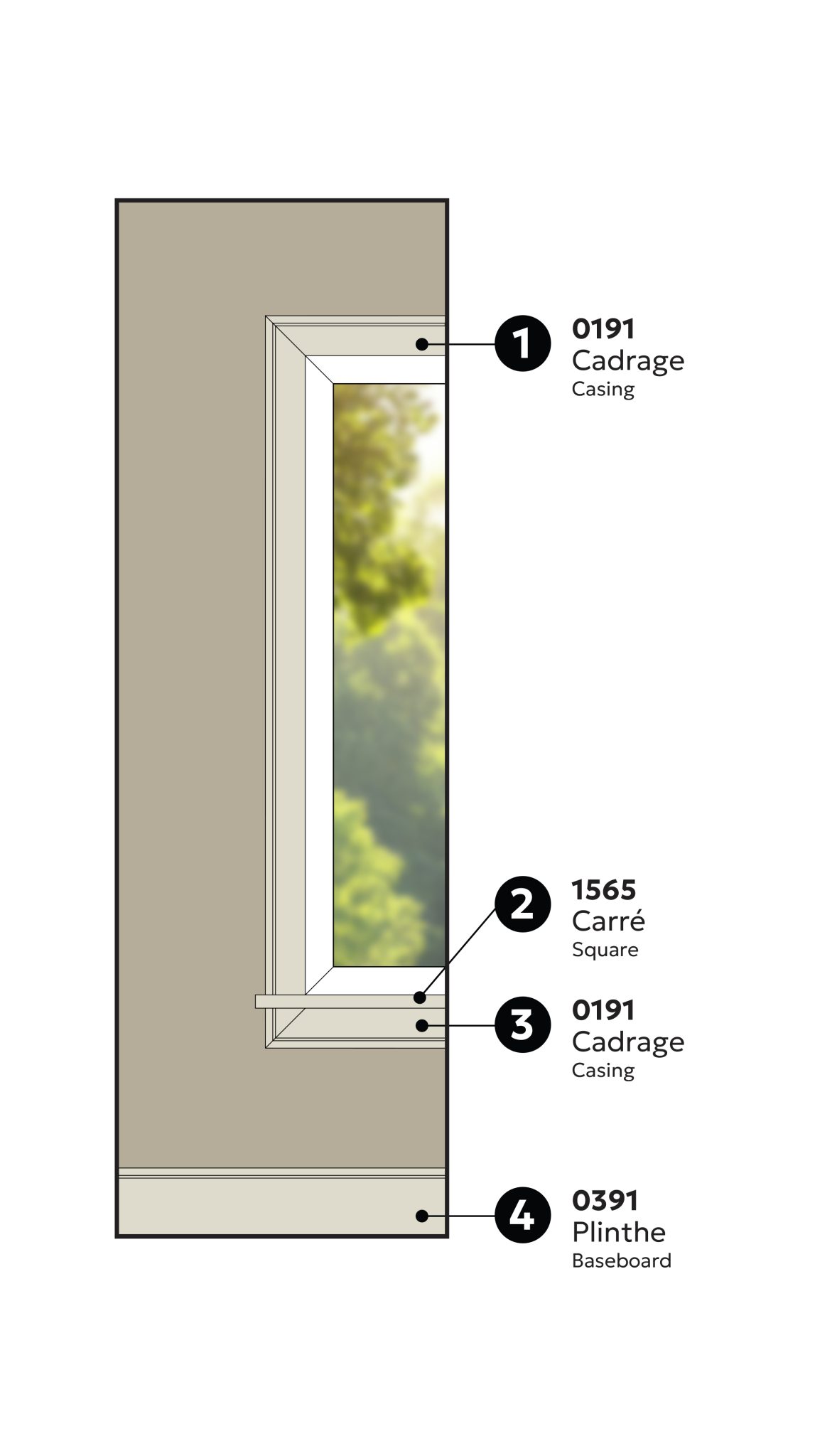

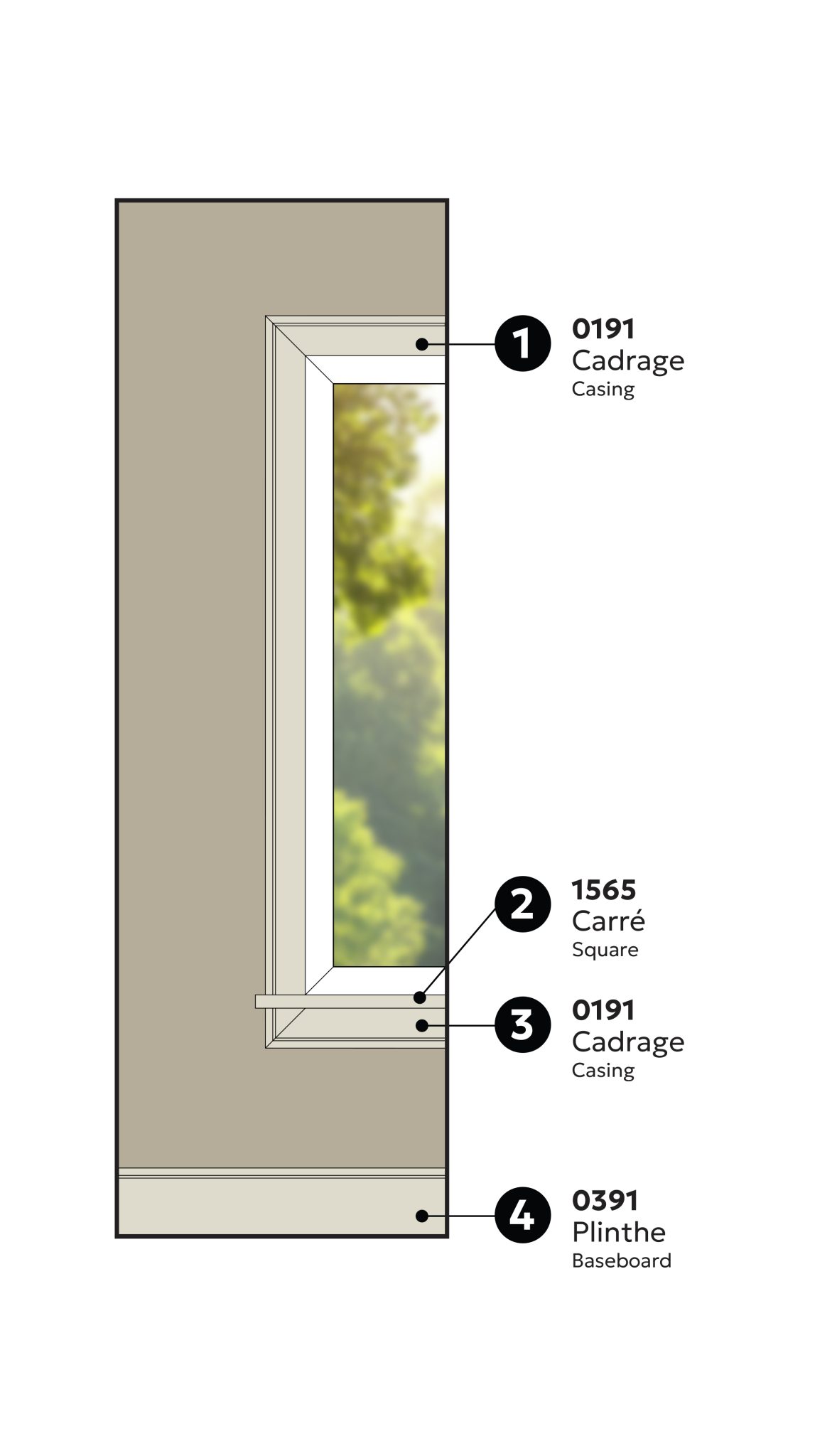

Arrangement 5

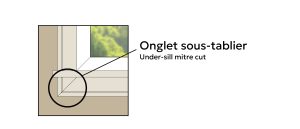

Under-Sill Miter Cut

The 45° cut under the window stool allows the moulding profile to follow seamlessly around the casing.

Below the stool, to continue the side casings and create the illusion of a continuous moulding, two small triangles (miters) are cut, then the bottom casing is finished with a moulding cut at a 45° angle on its ends.

The casings placed on top of the stool are cut straight, while the upper ends are cut at a 45° angle.

This technique creates a harmonious and elegant frame, with a polished finish that highlights every detail.

![]() Tips and tricks !

Tips and tricks !

Watch our web series to follow the correct installation order.

Learn how to make 45° cuts in our web séries.